64 West 48th Street - 2nd Fl

New York, NY 10036

T:(212)869-8762

TF:(800)360-2339

E:Info@Carreracasting.com

Expert@Carreracasting.com

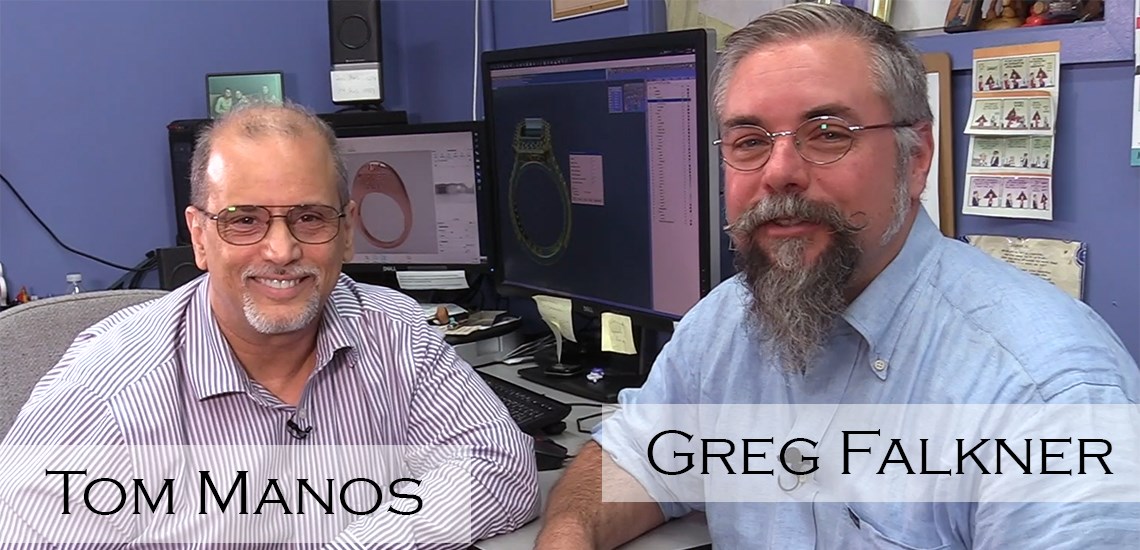

Learn how to "Perfect Your Trade" from Carrera Casting experts. In "Managing Your 3D Files" episodes Master jeweler and Carrera CAD/CAM Director Tom Manos teams up with Greg Falkner, Carrera's Product Development Manager, to share their real world knowledge and expertise in the areas of custom jewelry design, manufacturing and technology. Even better, this comprehensive series is free!

Managing Your 3D Files episodes will cover:

Learn how your maximize your designs for superior casting results by avoiding common CAD design errors. Having predictable casting and streamlined manufacturing results will drive your customer satisfaction while generating more business and profits. Stay tuned, many more Perfect Your Trade - Managing Your 3D Files episodes to come!

Learn how to "Perfect Your Trade" from Carrera Casting experts. In this episode, Creating and Checking STL Files, Master Jeweler and Carrera CAD/CAM Director Tom Manos discusses with Greg Falkner, Carrera's Product Development Manager the problems that ‘heavy files’ create and the use of file-checking programs to check and repair poor STL files.

Learn how to "Perfect Your Trade" from Carrera Casting experts. In this episode, Watertight Solids and Dirty Files, Master Jeweler and Carrera CAD/CAM Director Tom Manos discusses with Greg Falkner, Carrera's Product Development Manager on how to avoid non-watertight solids by checking for naked edges and dirty files.

Learn how to "Perfect Your Trade" from Carrera Casting experts. In this episode, Positioning & Planar Surfaces, Master Jeweler and Carrera CAD/CAM Director Tom Manos teams up with Greg Falkner, Carrera's Product Development Manager on the importance of positioning to eliminate gaps and avoid coplanar surfaces for successful Booleans.

In this episode, Booleans vs. Grouping, Master Jeweler and Carrera CAD/CAM Director Tom Manos teams up with Greg Falkner, Carrera's Product Development Manager on a) how to transform separate parts into water tight solids (Boolean) and b) moving multiple parts together through “Grouping” for a successful casting process.

Learn how to "Perfect Your Trade" from Carrera Casting experts. In Episode 5, Supporting Delicate Parts, Master Jeweler and Carrera CAD/CAM Director Tom Manos teams up with Greg Falkner, Carrera's Product Development Manager to solve common small parts model support issues for successful casting. Techniques shared include:

In this episode, Supports and Scaffolds, Master Jeweler and Carrera CAD/CAM Director Tom Manos teams up with Greg Falkner, Carrera's Product Development Manager master jeweler and Carrera CAD/CAM Director Tom Manos to solve common model support issues for successful casting.

In Episode Three "Spacing" Greg Falkner, Carrera's Product Development Manager, explores with master jeweler Carrera CAD/CAM Director Tom Manos frequent customer spacing issues. Tom points out why designing proper spacing into your jewelry design will ensure better survival through the casting process.

In Episode Two "Stamps, Logos and Draft Angles" Greg Falkner, Carrera's Product Development Manager, explores with master jeweler Carrera CAD/CAM Director Tom Manos frequent customer logo and lettering issues. Tom points out the best way to implement logo and lettering into your jewelry design to survive the casting process.

In Episode One "Maximizing Your Prongs and Walls", Greg raises some common problems many customers have when designing in CAD prongs and walls. Tom offers some easy steps that will maximize your prongs and walls for a successful casting process.